Nano Silver is a term used for colloidal silver preparations where the particle size of the silver in the solution is in a nano-particle size range.

First, we should explain the difference between Colloidal Silver vs. Ionic Silver, which can both be in the nano particle size range.

What is Ionic Silver Water?

Ionic Silver is a term used for positively charged atoms of silver. These silver ions are usually composed of just 1 atom of silver and are the smallest form of silver. They are missing an electron and carry a positive silver ionic charge.

Ionic Silver is always in the nanometer range of size, and so most Ionic Silvers on the market are also Nano Silver. Colloidal Silvers can also be in the nanometer range if it is produced properly. Ionic Silver is dissolved silver, or silver ions dispersed in water.

While Ionic silver has the same antimicrobial effects as Colloidal Silver, it contains no metals. A silver ion is a single atom while metals are actually metal crystals made up of 2 or more atoms. A pure Ionic Silver solution will not produce a “Tyndall effect”, but is still potent.

Research performed at Rice University revealed that ionic silver has a greater effect at killing bacteria than regular Colloidal Silver.

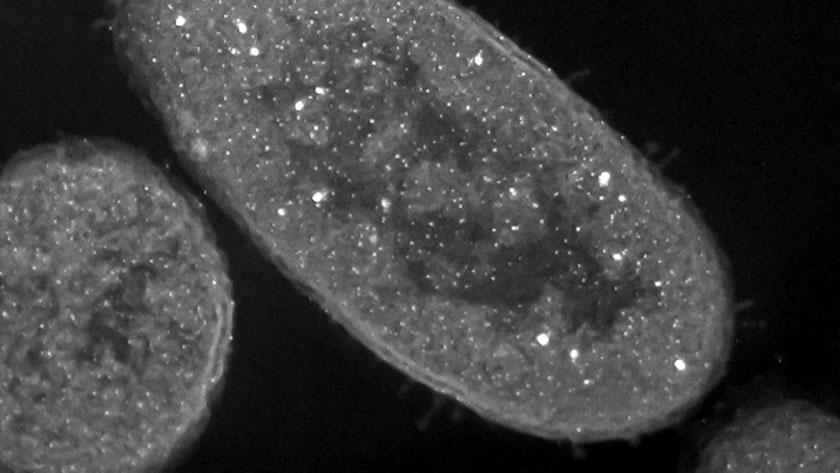

They found that “Silver ions delivered by nanoparticles to bacteria promote lysis, the process by which cells break down and ultimately die, making silver nanoparticles a superior and widely used antibacterial agent.”

What Does Colloidal Silver PPM Mean?

Colloidal Silver is a solution of pure metal silver particles suspended in water. Real colloidal silver is made up of 2 or more atoms of silver that are not bound to any other substance and can be separated out of the solution if desired. A high concentration of this type of silver with enough PPM’s will change the color of the water to a golden yellow tint. If the particle size of the silver is small enough and the ppm is lower, then the color of the solution can also be clear.

What is the most effective PPM for Colloidal Silver?

It is more of a matter of the particle size and the absorption into the body of the silver solution. It has been shown that 10 PPM to 20 PPM is a very effective concentration and also safe to drink.

It is extremely important to make sure that whatever Colloidal Silver product you are ingesting is made with only Steam Distilled water and Pure Silver (99.99% pure). Most companies will not spend the extra money to use steam distilled water as the equipment necessary is expensive. A lot of companies will state they use distilled water, but in reality, are using reverse osmosis water or deionized water. Both of these methods use filters or resins to “clean” the water. Deionized water uses resins that actually contain toxic materials to do the ion exchange. Accelerated Colloidal Silver, made with both Colloidal and Ionic silver, is always made with the highest quality double steam distilled water.

What Is Accelerated Colloidal Silver?

Accelerated Colloidal Silver contains both colloidal and ionic silver in the nanometer range (1.8 – 8.8 nm) and is the reason why it is clear. Using both the nano sized ions of silver and also a percentage of nano sized colloidal silver, it provides the benefits of both.

Additionally, in the future, we can adjust the composition of our silver solutions and will be coming out with a true 50/50 blend as we have the ability to produce true pure colloidal silver. Our current formula has approximately 80 percent ionic silver and 20 percent nano colloidal silver, thus giving a clear solution that still gives a “Tyndall effect”.

Using a laser beam in a dark room, the Tyndall effect can be observed. The Tyndall effect is the light scattering effect when a beam of light hits very fine particles in a colloidal suspension. This is one way to verify you have an ultra fine silver (or nano silver) solution.

What to Look For When Choosing Your Silver Solution

There are very few makers of true colloidal silver as it is a difficult and slow process, and the silver has a propensity for clumping together and falling out of solution if made incorrectly. Runaway voltage is a real problem in making metal colloidal solutions and we use a computerized system for continually measuring the voltage used during our process to make sure we never have runaway voltage that can cause large particle sizes. This continuous monitoring makes sure we are consistent with each batch and you are getting a true nano silver particle within the appropriate nano sized range.

Ionic Silver, because the particle size is so small, usually does not reflect light well and thus the Tyndall effect could be absent. If you shine a laser into a silver solution that does not generate a Tyndall effect, then there is not much colloidal silver in the solution. Worse yet, it might be a silver salt solution. Some manufacturers might be using distilled water, but because of the process they are using to make the silver, “High Voltage Plasma Arc”, the silver is produced in an environment where the nitrogen compounds in the air in the chamber make nitrate compounds. The reason why manufacturers use High Voltage Arc process is that it is a much faster way to make silver. But the HV Arc process not only creates ionic silver, but melts silver off the metal rods used in the process. This “melted” silver is inferior for a number of reasons to properly made silver. Melted silver can form misshapen silver particles and not be entirely round. Also, melted silver can form much larger particle sizes above 10nm which then makes the silver much less effective. We have to realize that for silver to work, the particle size has to be very small. Most cells are 4000nm in size. We need to have silver that is extremely small to invade the cell wall. A silver particle that is 30 or more nano meters will be virtually ineffective and at this size, the zeta potential is very small, and thus the silver is likely to fall out of solution.

One common chemical created by this process creates nitric acid, which then “dissolves” the silver in solution and can create Silver Nitrate. Silver Nitrates were manufactured by pharmaceutical companies years ago, used as eye drops for infants to prevent infections leading to blindness. Whenever silver solutions are produced in this manner, dangerous silver nitrates compounds are also produced which is what these pharmaceutical silver became infamous for and is the reason they are no longer used. There are still manufacturers making their silver in this way and are currently on the market.

Again, this is the reason we use a low voltage process and our system uses a completely closed system that does not allow any air into our chamber during the manufacturing process. Not only does this completely eliminate any chances of producing nitrates, but also prevents little things like dust from getting into our product as any level of contamination could disrupt the colloids and make them fall out of solution.

In Conclusion…

Many marketers are now using the term Nano to create buzz around silver solutions and nano silver benefits, but all good silver solutions should be in the nano size range. Nano is just a term describing the size of particles. It is true that the smaller the silver particle the better the effectiveness, and also when silver is in the nano range and not mixed with or bound to any other chemicals, then it is safe to use in the 10-20 PPM concentration range.

If your silver solution does not create a Tyndall effect, then it is either just pure ionic silver with no colloids, a silver salt solution, or just plain water with hardly any silver in it at all. There are benefits to both Ionic and Colloidal silver, so we make a solution that has both.

Sara Banta

Sara Banta is a Stanford University Graduate with a Degree in Economics and Psychology, and a certified Natural Supplement Expert & Graduate of the Institute for Integrative Nutrition. Sara is the Founder of Accelerated Health Products and host of the health & wellness podcast, Accelerated Health Radio.